Batteries are the backbone of our modern world designed to power everything from smartphones to electric vehicles. The trend for cleaner mobility and sustainable energy requires higher performance and longer lifespans going along with more accurate ways to monitor and maintain batteries. This necessitates to accurately determine two critical parameters: State-Of-Charge (SoC) and State-of-Health (SoH). They reflect the amount of energy the battery can still deliver and the degradation of the battery’s performance over time, respectively.

Over the years, different battery types have been developed, each with specific properties and characteristics.

- Lead-acid batteries are robust and well-suited for automotive applications and UPS.

- Nickel-cadmium (NiCd) batteries are durable and have a long shelf life.

- Lithium-ion (Li-ion) batteries are lightweight and offer high energy density and long cycle life, making them ideal for electric mobility.

Beyond chemistry, batteries come in different formats, such as cylindrical and pouch, and each type is selected based on factors like energy density, thermal management, and the intended application.

Battery Monitoring

For safe and efficient operation, a battery’s SoC and SoH are tracked by a Battery Management System (BMS). Since these parameters cannot be measured directly, they must be estimated. Traditional BMS units rely on voltage, current and temperature measurements. As batteries become more advanced and operate under diverse conditions, these measurements alone are no longer sufficient. To improve accuracy, modern approaches integrate additional sensing techniques such as pressure monitoring and impedance spectroscopy to provide complimentary data. This richer information enhances efficiency and extends battery lifetime.

Quantum Sensors

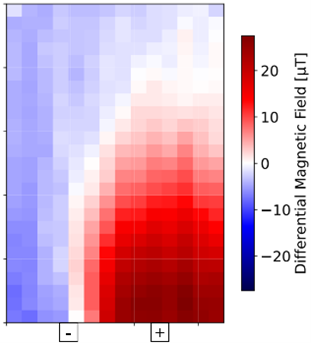

Quantum sensors are among the most advanced technologies recently applied to battery systems. With their high sensitivity and precision in measuring magnetic fields, quantum sensors offer a non-invasive way to estimate SoC and SoH. In addition, they can localize defects and hotspots by capturing the tiny magnetic fields generated by the battery. These measurements can be taken at single points or expanded into a full magnetic field map, opening new pathways for battery diagnostics and monitoring.

The Cynergy4MIE Project

Within the Cynergy4MIE project, researchers at SAL, EDI and FAU focus on Li-ion battery characterization using a state-of-the-art quantum sensor developed at FAU. This sensor achieves a sensitivity of

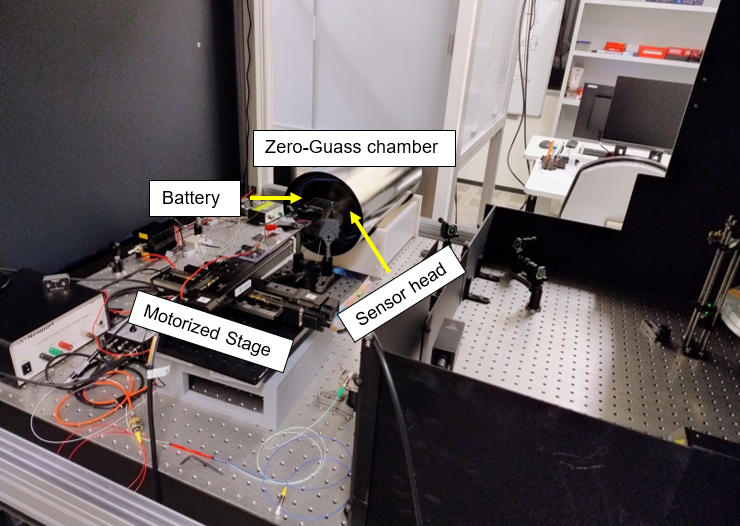

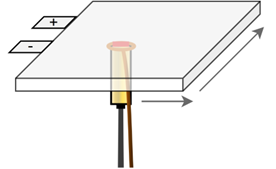

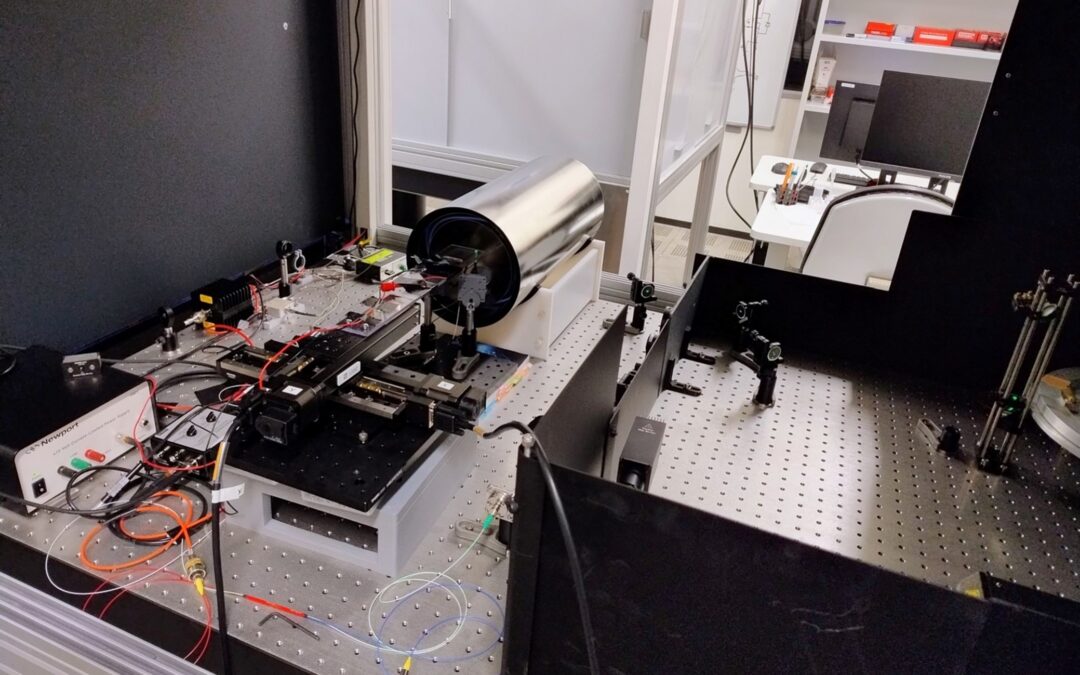

enabling the detection of weak magnetic fields. In preliminary experiments, it was used to study the current distribution within Li-ion battery cells. The experimental setup (Figure 1) employed a motorized stage to generate a complete map of the magnetic field. To ensure measurement accuracy, the sensor head was placed inside a zero-Gauss chamber to shield it from external magnetic fields, including the earth’s field and nearby laboratory equipment.